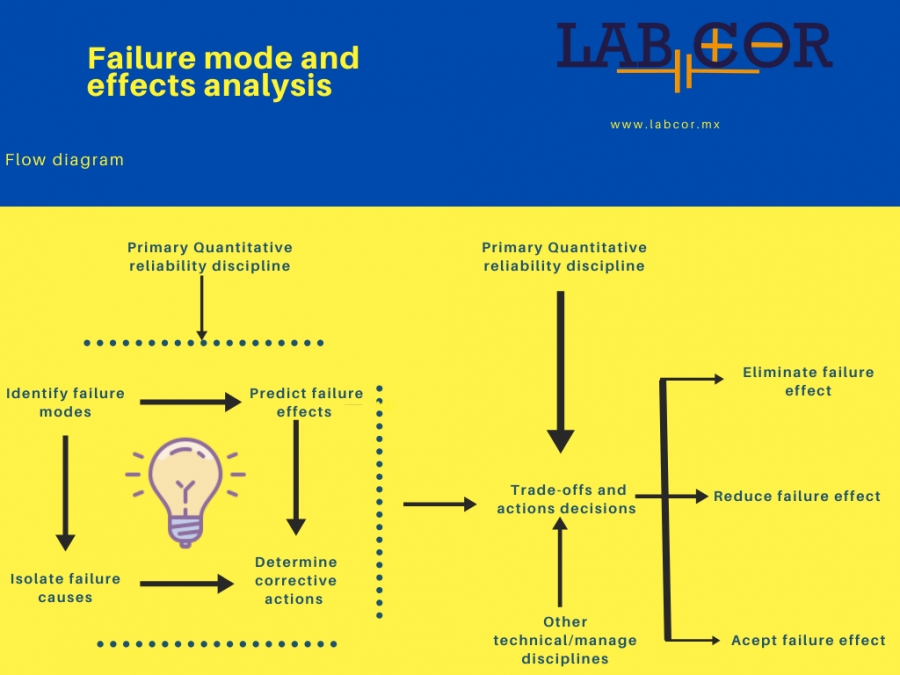

The analysis assumes a failure point of view and identifies potential modes of failure along with their failure mechanism. The effect of each failure mode then is

traced up to the system level. Each failure mode and resulting effect is assigned a criticality rating, based on the probability of occurrence, its severity, and its delectability. For failures scoring high on the criticality rating, design changes to reduce it are recommended.

Following this procedure provides a more reliable design. Also such correct use of the F M E A process results in two major improvements: (1) improved reliabilityby anticipating problems and instituting corrections prior to producing product and (2) improved validity of the analytical method, which results from strict documentation of the rationale for every step in the decision-makingprocess.

Two major limitations restrict the use of FMEA: (1) logic trees used for this type ofanalysis are based on probability of failure at the component level and (2) full application is very expensive. Basing logic trees on the probability of failure is a problem because available component probability data are specific to standard conditions and extrapolation techniques cannot be used to modify the data for particular applications.