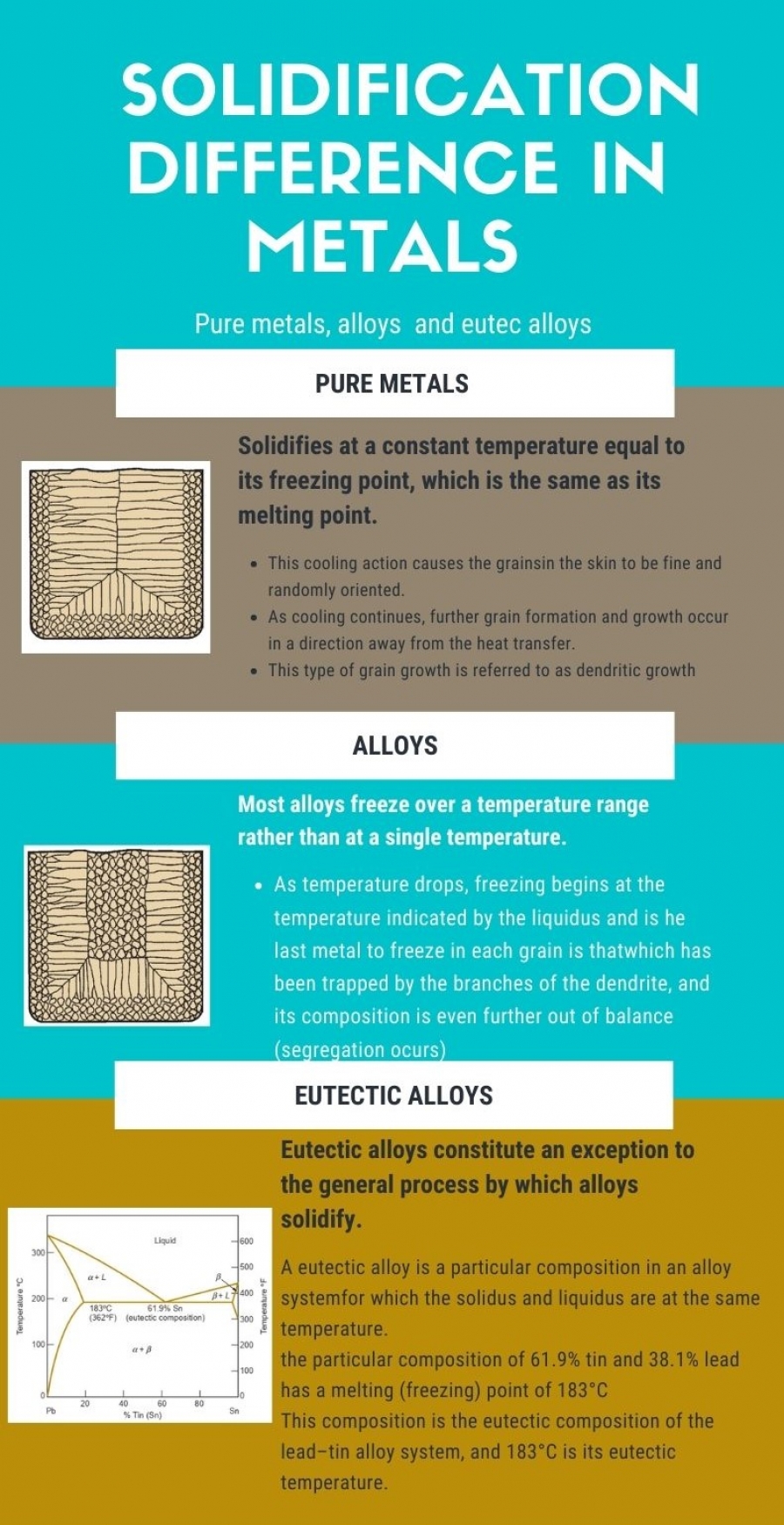

Pure Metals A pure metal solidifi es at a constant temperature equal to its freezing point, which is the same as its melting point. The melting points of pure metal are well known and documented. The process occurs over time called a cooling curve. The actual freezing takes time, called the local solidification time in casting, during which the metal’s latent heat of fusion is released into the surrounding mold. The total solidification time is the time taken between pouring and complete solidifi cation. After the casting has completely solidifi ed, cooling continues at a rate indicated by the downward slope of the cooling curve. Because of the chilling action of the mold wall, a thin skin of solid metal is initially formed at the interface immediately after pouring. Thickness of the skin increases to form a shell around the molten metal as solidifi cation progresses inward toward the center of the cavity. The rate at which freezing proceeds depends on heat transfer into the mold, as well as the thermal properties of the metal. It is of interest to examine the metallic grain formation and growth during this solidification process. The metal which forms the initial skin has been rapidly cooled by the extraction of heat through the mold wall. This cooling action causes the grains in the skin to be fine and randomly oriented. As cooling continues, further grain formation and growth occur in a direction away from the heat transfer. Since the heat transfer is through the skin and mold wall, the grains grow inwardly as needles or spines of solid metal. As these spines enlarge, lateral branches form, and as these branches grow, further branches form at right angles to the fi rst branches. This type of grain growth is referred to as dendritic growth, and it occurs not only in the freezing of pure metals but alloys as well. These treelike structures are gradually filled-in during freezing, as additional metal is continually deposited onto the dendrites until complete solidifi cation has occurred. The grains resulting from this dendritic growth take on a preferred orientation, tending to be coarse, columnar grains aligned toward the center of the casting.

Most alloys freeze over a temperature range rather than at a single temperature. The exact range depends on the alloy system and the particular composition. As temperature drops, freezing begins at the temperature indicated by the liquidus and is completed when the solidus is reached. The start of freezing is similar to that of the pure metal. A thin skin is formed at the mold wall due to the large temperature gradient at this surface. Freezing then progresses as before through the formation of dendrites that grow away from the walls. However, owing to the temperature spread between the liquidus and solidus, the nature of the dendritic growth is such that an advancing zone is formed in which both liquid and solid metal coexist. The solid portions are the dendrite structures that have formed sufficiently to trap small islands of liquid metal in the matrix. This solid–liquid region has a soft consistency that has motivated its name as the mushy zone. Depending on the conditions of freezing, the mushy zone can be relatively narrow, or it can exist throughout most of the casting. The latter condition is promoted by factors such as slow heat transfer out of the hot metal and a wide difference between liquidus and solidus temperatures. Gradually, the liquid islands in the dendrite matrix solidify as the temperature of the casting drops to the solidus for the given alloy composition. Another factor complicating solidifi cation of alloys is that the composition of the dendrites as they start to form favors the metal with the higher melting point. As freezing continues and the dendrites grow, there develops an imbalance in composition between the metal that has solidifi ed and the remaining molten metal. This composition imbalance is fi nally manifested in the completed casting in the form of segregation of the elements. The segregation is of two types, microscopic and macroscopic. At the microscopic level, the chemical composition varies throughout each individual grain. This is due to the fact that the beginning spine of each dendrite has a higher proportion of one of the elements in the alloy. As the dendrite grows in its local vicinity, it must expand using the remaining liquid metal that has been partially depleted of the fi rst component. Finally, the last metal to freeze in each grain is that which has been trapped by the branches of the dendrite, and its composition is even further out of balance. Thus, there is a variation in chemical composition within single grains of the casting. At the macroscopic level, the chemical composition varies throughout the entire casting. Since the regions of the casting that freeze fi rst (at the outside near the mold walls) are richer in one component than the other, the remaining molten alloy is deprived of that component by the time freezing occurs at the interior. Thus, there is a general segregation through the cross section of the casting, sometimes called ingot segregation.

Eutectic alloys constitute an exception to the general process by which alloys solidify. A eutectic alloy is a particular composition in an alloy system for which the solidus and liquidus are at the same temperature. Hence, solidification occurs at a constant temperature rather than over a temperature range, as described above. The effect can be seen in the phase diagram of the lead–tin system. Pure lead has a melting point of 327°C, while pure tin melts at 232°C. Although most lead–tin alloys exhibit the typical solidus–liquidus temperature range, the particular composition of 61.9% tin and 38.1% lead has a melting (freezing) point of 183°C. This composition is the eutectic composition of the lead–tin alloy system, and 183°C is its eutectic temperature. Lead–tin alloys are not commonly used in casting, but Pb–Sn compositions near the eutectic are used for electrical soldering, where the low melting point is an advantage. Examples of eutectic alloys encountered in casting include aluminum–silicon (11.6% Si) and cast iron (4.3% C).